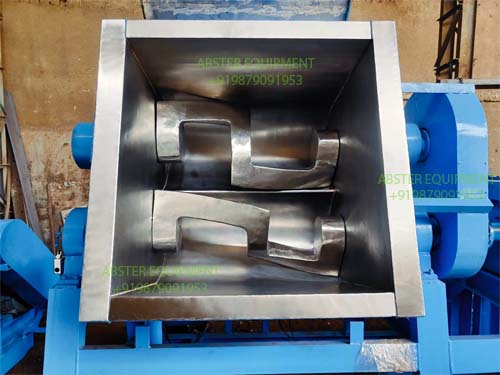

1000L Sigma Mixer

1000L sigma mixer machine has a double 'U' shaped container welded together inside which rotates 2 (two) 'Z' type sigma blades in opposite directions of each other sigma mixer blade. The clearances between the walls and the container are kept to a minimum for optimum efficiency in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks which are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakless operations. The kneader is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. For cooling and heating jackets are provided. the machine also called Z BLADE MIXER

1000L sigma mixer machine has a double 'U' shaped container welded together inside which rotates 2 (two) 'Z' type sigma blades in opposite directions of each other sigma mixer blade. The clearances between the walls and the container are kept to a minimum for optimum efficiency in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks which are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakless operations. The kneader is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. For cooling and heating jackets are provided. the machine also called Z BLADE MIXER

![]()

Sigma mixers are used in a number of food and commercial adhesive applications. Ingredients are blended until the consistency is correct. The ingredient is then tipped out of the mixer and forwarded to the next step in the process.

Sigma mixers are used in a number of food and commercial adhesive applications. Ingredients are blended until the consistency is correct. The ingredient is then tipped out of the mixer and forwarded to the next step in the process.

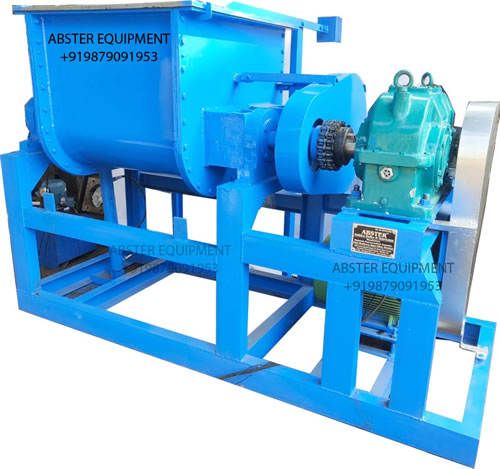

These types of machines are available in M.S. And S.S. construction. The kneader can be tilted by means of a mechanical system or manually and for bigger models beyond 250 Kgs we provided hydraulic tilting.

Hydraulic tilting system is provided with complete power pack, electric motor, pressure valves, pipes, fittings, cylinders and hoses which makes the tilting mechanism quick, easy and simple to operate.

![]()

Applications:

Double Arm Sigma Blade Mixers are suitable for many applications, including: Sealing compounds, asphaltic derivatives, mastics, hot-melts, floor coverings, colorings, rubber base, master-batches, chewing gum, rubber compounds, silicone, lubricating greases, dispersed pigments, butyl, gums and adhesives, ceramic paste, polyester compounds, greasy inks, pencil leads, explosives, powders to granulate, PVC coatings, resins, soap, brake linings, carbon electrodes, celluloid, Bakelite, battery paste, polishing pastes, …

LABORATORY DOUBLE ARM SIGMA BLADE MIXERS

Laboratory Mixers are available in sizes ranging from 3 Liters to 10 liter working capacity. Variable speed drive on the blades standard. Stainless steel construction standard, jacketed is standard.

Sigma Mixer or Sigma Kneader is generally used for heavy duty mixing, kneading, dough knaeding, uses in the Paint, Pigment, food, adhesives, chemical, pharmaceutical, dyestuff industries.

sigma mixer machine,sigma mixer kneader, sigma mixer extruder, Z blade sigma mixer, double arm sigma mixer, food grade sigma mixer, heavy duty sigma mixer, bubble gum sigma mixer,sigma dough mixer, liquid soap sigma mixer, lab sigma mixer, sigma mixer manufacturer, sigma kneader manufacturer, sigma mixer exporter, sigma kneader exporter, sigma mixer manufacturer ahmedabad, Sigma mixer manufacturer india, sigma mixer exporter india,

Sigma Mixer Capacity

| Model(L) | ABF-1 | ABF-2 | ABF-5 | ABF-10 | ABF-50 | ABF-100 | ABF-200 | ABF-300 | ABF-500 | ABF-1000 | ABF-1500 | ABF-2000 | ABF-3000 | ABF-4000 | ABF-5000 | ||||||

| volume(L) | 1 | 2 | 5 | 10 | 50 | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | ||||||

| Steam pressure(Mpa) | 0.3 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | 0.34 | ||||||

| Hot oil circulation(Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | ||||||

| Electric heating(Kw) | 0.5 | 1 | 1.5 | 2 | 3-6 | 4-11 | 6-15 | 6-18 | 12-24 | 18-36 | 32-45 | / | / | / | / | ||||||

| Fast Rpm | 45 | 42 | 60 | 45 | 35 | 36 | 36 | 40 | 30 | 35 | 40 | 35 | 32 | 30 | 35 | ||||||

| Slow rpm | Speed ratio 1.0-1.9 as option, according to materials features. | ||||||||||||||||||||

| Main motor (Kw) | 0.37-1.1 | 0.55-1.5 | 0.75-2.2 | 1.5-3 | 3-5.5 | 4-11 | 5.5-15 | 5.5-18 | 11-45 | 18.5-75 | 22-90 | 45-160 | 55-190 | 75-250 | 90-225 | ||||||

| Vacuum | ≤-0.094Mpa | ||||||||||||||||||||

| Discharge | 1.manual (for small capacity) 2.bottom ball valve 3.electric tilting 4.screw extruding | ||||||||||||||||||||

Products

- 500L double arm sigma blade kneader mixer

- 1000L Sigma Mixer

- Double Sigma Arm Mixer Machine

- High Viscosity Screw Extruder Double Sigma Blade Kneader Mixer

- Hot Melt Adhesive Sigma MixerDough Sigma Blade KneaderZ Blade Kneader MachineChewing Gum And Bubble Gum Kneader Machine

- Softgel Capsule Manufacturing Equipments

- Silicone Rubber Sigma Blade Mixer

- Hot Melt Adhesive Sigma Mixer

- High Viscosity Screw Extruder Double Sigma Blade Kneader Mixer

- Gelatin Cooking Mixer Manufacturer

- Softgel Capsule Manufacturing Equipments

- Gelatin Cooking Mixer Manufacturer

- Gelatin Holding Tank

- Reaction Vessel

- V Cone Blender Mixer

- Condenser / Heat Exchanger

- Pressure Vessels

- Distillation Unit

- Pilot Reaction Unit

- Sigma Mixer

- Ribbon Blender

- Tray Dryer

- ETO Sterilizer Machine

- Pressure Nutsche Filter(PNF)

- Membrane Filter Holder

- Ethylene Oxide Sterilizer

- Attritor Mill

- Bead Mill

- ETO Sterilizer for Hospital

- Cath lab ETo Sterilizer

- Horizontal Autoclave

- Cylindrical Autoclave

- Eto Sterilizer Exporter in India

- Reaction Vessel Exporter in India

- sigma mixer manufacturer

- Sigma Mixer Kneader

- sigma mixer manufacturer india